Lumping and clustering during freezing are always an issue that makes food processor headache. It effects on frozen product appearance by sticking freezing tendency, especially for foods small in size and varied in shape, from fruit (half, chunk, etc..) to shrimp.

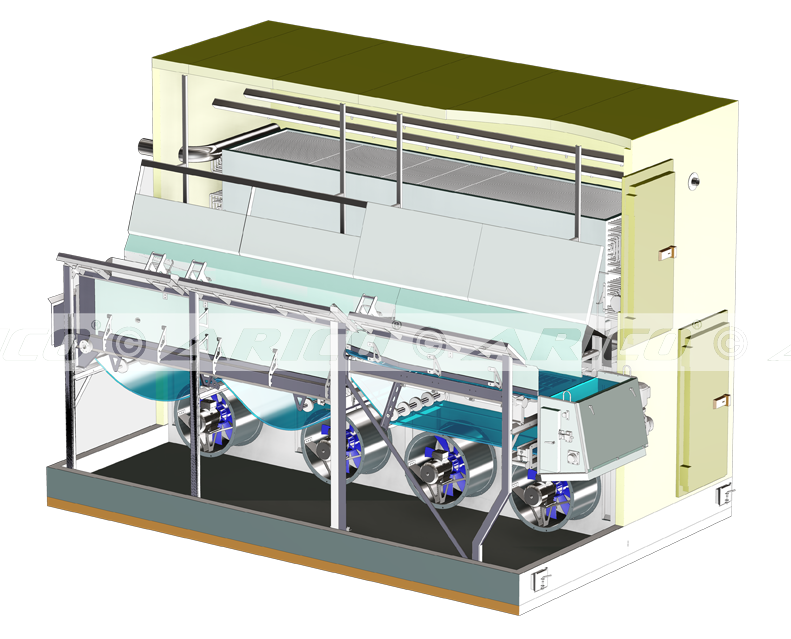

Arico’s Fluidized IQF, by using Fluidized Effect, is the perfect solution for this issue. It is ideally to freeze small, delicate and hard to handle foods of differing shapes and sizes, from fat, juicy (mango, strawberry…) to tiny size (shrimp smaller than 300/400…) foods.

The rich flavor, texture and quality of frozen food can be preserved with short freezing time, no deformation, lower weight-loss and non-sticking.

Advanced Freezing Technology:

Efficiency and High productiveness:

Quality and Hygiene Design:

Low Energy Consumption Innovation:

Tailor-made Solution and Customization:

|

|

|  | |

| Module Fluidized IQF |