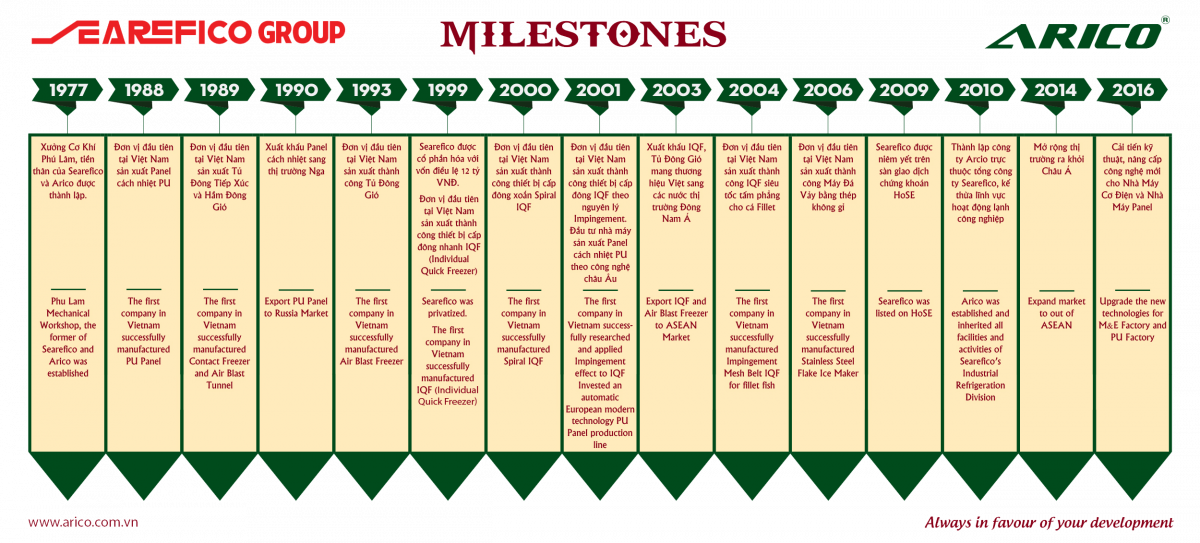

Arico has consistently been a leading company in Vietnam’s food and seafood machinery industry. Our journey began in 1977 with the establishment of Phu Lam Mechanical Workshop, under Decision No. 1501/QD-UB issued by the People’s Committee of Ho Chi Minh City. During this period, we launched our first product-a Block Ice Making System-which served the emerging seafood processing industry of the 1970s.

Refrigeration systems and freezing technology have been the cornerstone of Arico’s development. For over 40 years, we have proudly played a pivotal role, contributing to the growth and advancement of Vietnam’s food and seafood industry.

On November 18th 1977, Phu Lam Mechanical Factory was established by Decision No. 1501/QD-UB of People’s Committee of Ho Chi Minh City.

In early 1978, Phu Lam Mechanical Workshop successfully researched and developed the Automatic Block Ice Making System. This was the foundation on which our knowledge and experience in Refrigeration Industry and Food and Seafood Industry were formed and built up.

In late 1988, Phu Lam Mechanical Workshop proudly announced that it was the first company in Vietnam who successfully manufactured Polyurethane (PU) panel. This milestone helped local food and seafood processors and exporters increase the rate of localization of their insulation structures resulting in investment costs reduction. Since then, Arico became the leading PU panel supplier in domestic market. In 1991, the Company marked another significant milestone when it became the qualified firm which exported PU panel to Russia.

In the middle of 1990, Phu Lam Mechanical Workshop contributed another important milestone to Vietnam Food and Seafood Processing Industry by launching the first Contact Freezer made in Vietnam in Mekong Delta region. We proudly became the leading company in this industry. This milestone marked Arico’s first legacy in Food and Seafood Industry Freezer machinery.

On April 1st 1993, Seaprodex Refrigeration Industry Corporation (Searefico) was established by Decision No. 95/TS/QDTC, as a State-owned Enterprise directly belonged to Vietnam Seaproducts Import and Export Joint Stock Corporation. Searefico was engaged in Engineering and Construction Industry.

After the establishment, Searefico merged Phu Lam Mechanical Workshop, who was the leading firm in freezing and processing technologies in Mekong Delta. Under the Industrial Refrigeration sector, it provided consultancy, design, manufacturing, and engineering for industrial refrigeration system used in food and seafood, beverage, and pharmaceutical industry.

Also in this year, Searefico with the foundation inherited from Phu Lam Mechanical Workshop, successfully manufactured first Vietnam-made-Air Blast Freezer and Tunnel Freezer which properly met increasing demand of Vietnam Seafood Processing Industry during the shifting era from exporting block, raw seafood to individual frozen and high quality. Thanks to high localization-rate of these products, Vietnamese food and seafood processors and exporters not only increased their competitiveness by reducing the dependence on expensive machines from Europe and US, but also partially formed a foundation for domestic seafood industry booming during next decades.

Three years later, in November 1996, Searefico merged Sea Refrigeration Electrical Engineer (Searee), who was the leading company in refrigeration system and freezing technologies in Middle of Vietnam, thus solidifying its position as the leading provider of Food and Seafood technology. This event marked a notable milestone, Searefico became the top-leading company in its industry in the country.

In 1999, as its rapid growth, Searefico was privatized. This event gave a great chance for Searefico to not only reinforce its leading position in Food and Seafood processing machinery industry, but also explore its ability and capability to serve in other industries such as F&B, M&E, and Industrial and Commercial Machinery.

In 2009, Searefico was listed on HoSE and became a public company which is evaluated as the leading organization in its industry.

Today, Searefico joined in top 500 biggest companies in Vietnam and the group is ranked as the second M&E Service Supplier in the country.

The former of Arico was Industrial Refrigeration Division (IRD) of Searefico. This division played an important role during the development of Searefico.

By inheriting the technical foundation and research achievement from Phu Lam Mechanical Workshop and Searee, IRD remarkably contributed its values to the significant development of Vietnam Seafood Processing and Exporting Industry.

In 1999, we introduced Vietnam-made-Mesh Belt Individual Quick Freezer to the domestic market. This event marked a very important milestone in the Vietnam Seafood Industry. Instead of importing expensive IQF from Europe, US and Japan, Vietnamese seafood processing firms had a wonderful option to reduce investment cost which enables them to enhance their competitiveness.

Based on our Clients’ trust, Arico developed a series of freezers to adapt to an increasing demand of various kinds of seafood products to be processed and exported from the domestic seafood players. Most of the remarkable milestones of Arico were achieved during 2000s which is considered as the booming era of Vietnam Food and Seafood Industry.

In 2000, we became the first domestic company successfully manufactured the Spiral Individual Quick Freezer.

In 2001, we were the pioneer firm who invested in an automatic European modern technology PU panel production line.

In 2003, we exported our IQF and Air Blast Freezer to ASEAN market. This event marked a great milestone that Arico was the first Vietnamese machinery supplier expanded its business out of the country and gained the trust from the Clients.

In 2004, we became the first Vietnamese company successfully manufactured Impingement Steel Belt IQF for fillet fish and packaged food.

In 2006, we became the first Vietnamese company successfully manufactured 30 Tons Stainless Steel Orbital Ice Storage.

During the period of 2000s, with a strong technical foundation and professional R&D activities, we were always the first company who introduced new machines and technologies to Vietnam Food and Seafood Industry.

In 2007 October 22nd, Arico was established and inherited all activities of Searefico’ s Industrial Refrigeration Division.

In 2010, Arico operated the new facility 25,000 sqm in Tan Tao industrial zone, Binh Tan District, HCMC.

Not limiting within Vietnam and ASEAN market, in 2014, Arico brought its value to others markets, such as India. Our commitment is to be always in favor of your development by continuously researching, applying and upgrading new technology, not only on the design but also on manufacturing, and bringing more added-value to our Clients.

HOSHIZAKI Group Company

___The Journey of Made in Vietnam – Japanese Technology___

In March 2025, Hoshizaki, a Global leading Manufacturer of commercial equipment for food and beverage services, has strategically acquired a 51% share in Arico, a prominent Vietnamese company specializing in industrial refrigeration and freezing technology for the food and seafood industries. This majority stake not only solidifies Hoshizaki’s position in Southeast Asia but also enables the company to leverage Arico’s extensive expertise and innovative solutions to drive business expansion in the region. Together, the two companies aim to deliver enhanced value to clients by combining advanced technology with a shared commitment to excellence, paving the way for sustainable growth and innovation in the global market.

A new journey has started.

| NAME | : ASIA REFRIGERATION INDUSTRY JOINT STOCK COMPANY |

| ABBREVIATION | : ARICO |

| ADDRESS | : LOT 25-27, TRUNG TAM ROAD, TAN TAO INDUSTRIAL ZONE, TAN TAO WARD, HO CHI MINH CITY, VIETNAM |

| BUSINESS NUMBER | : 0305429178 |

| TELEPHONE | : +84 28 375 45678 |

| FAX | : +84 28 375 45679 |

| : info@arico.com.vn | |

| INDUSTRY GROUP | : REFRIGERATION, FOOD INDUSTRY & BUILDING INSULATION |

We provide master planning, design, construction, and maintenance services, ensuring seamless collaboration across all disciplines to deliver efficient designs and successfully execute projects.

We specialize in:

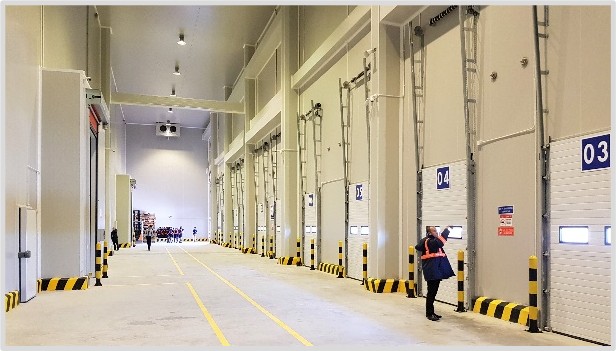

| Industrial Refrigeration Solution We are a Design & Build (D&B) contractor for Ammonia refrigeration system, Freon systems, Cold storage, M&E services, Utility system for food processing plants, factory and building, cold chain, etc. |

Food Processing Equipment We design, manufacture, install, and commission (T&C) food processing equipment customized to our clients’ needs. Our products include solutions for processing, cooking, freezing, and chilling seafood, ready-to-eat meals, fruits, vegetables, poultry, and more. |  |

| Cold Storage Warehouse Solution We deliver complete cold storage packages, from design to installation, serving sectors like clean rooms, cold rooms, insulated buildings for F&B processing, logistics, pharmaceuticals, HORECA, etc. |

We offer our clients a diverse range of products and services, from complete turn-key projects to customized individual equipment solutions.

Our expertise includes designing and constructing food processing plants, encompassing refrigeration systems, processing lines, freezing equipment, cold storage, and SCADA/FMS systems. Our product portfolio consists of:

As a one-stop solution provider, we are committed to delivering high-quality, cost-effective engineering designs, services, and products to help enhance your capacity. By following a structured collaboration process, we ensure our work is completed on time and within budget.

Arico, the company who specializes in Refrigeration Engineering and Food Industry, provides premium mechanical and electrical products and services especially for Aquaculture and Food Industries to meet specific demands of our Clients with modern and advanced technical specifications.

We are always in favor of your development and always want to be seen as the most trustworthy, creative and innovative partner in the Industries we serve.

We research, innovate, develop and offer state of art and suitable solutions to our Clients in the industries we serve . We are here to ensure the Availability, Reliability, Innovation, Conformity and Outstanding quality deliver to our partners.

We create a favorable, advanced working environment and healthy, happy life for the community we belong.

|

AGILITY

|

RELIABILITY

| |

INNOVATION

| |

CONFORMITY

| |

ONE TEAM

|

HEALTH, SAFETY AND ENVIRONMENT

We focus on creating value through excellence in people, quality and innovation, while striving to avoid any harm to our employees, community and environment. Arico has conducted business according to the following guiding principles:

We care about people and the environment.

More often than not, new products design and development is a crucial factor of any organizational survival in the fast changing world today and Arico is not an exception in this context. Due to continuous change in technology and development as well as Clients’ preference, we always aim to seriously invest in our R&D works which is situated at the front end of our product’s innovation life circle.

Arico R&D activities are focused on two main models: one task engages in directly Developing New Products and another involves in Applied Research in technology field.

We always put new innovative technologies on our top priority in Designing and Manufacturing to continuously improve our products and services quality in order to meet the increasing demands from Food Processing Industry Requirement.

With state of the art sheet metal automatic cutting and bending deployment line including Fiber Laser Cutting machines, CNC Bending machines, Surface Treatment line …, Arico provides technological platform for our engineers to deploy newest designing method in CAD, CAM, 3D Sheet Metal and FEA (Finite Element Analysis), thus we innovate, improve and develop not only our products and services but also our solutions to serve Food Processing Industry.

Thanks to all these efforts, during the Company’s developing history, Arico is always the Pioneer who brought to Vietnamese Food Processing Industry modern machines and equipment with state of the art technologies. By seriously investing in R&D, Arico proudly contribute its values for sharpening Vietnamese Seafood Industry as we see it today.

| Arico’s products are made of Stainless Steel and Food Grade Materials with corrosion risk-free. With our skillful staff and employees, our Quality and Hygiene policy is confidently reinforced and continuously improved. Before delivering and taking duty in your plant, all of Arico equipment must be passed the dry test. At site, the installation works are done by Arico experts who have full knowledge of not only the equipment but also Clients’ needs. We aim to design and manufacture hygiene products that meet the increasing requirements in the fast changing food industry. In our machines and equipment, all the product contact surface must be easily cleanable and dismountable. CIP (Cleaning in Place), WSFC System (Water Sterilizing, Filtering and Circulating System), are available to make cleaning and water saving are easier than ever before. |

|  |

|  |

|

Hygiene and Quality are our top priority to provide Available, Reliable, Innovated, Conformable and Outstanding solutions and equipment for Food Industry. Your Continuous and Satisfactory operation is our guarantee. Unexpected and Costly Downtime Elimination is the added value we offer.

Hygiene and Quality are our top priority to provide Available, Reliable, Innovated, Conformable and Outstanding solutions and equipment for Food Industry. Your Continuous and Satisfactory operation is our guarantee. Unexpected and Costly Downtime Elimination is the added value we offer.