Ranging from Spiral IQF to Complex Spiral System for heating, baking and other purposes to close the food processing circle.

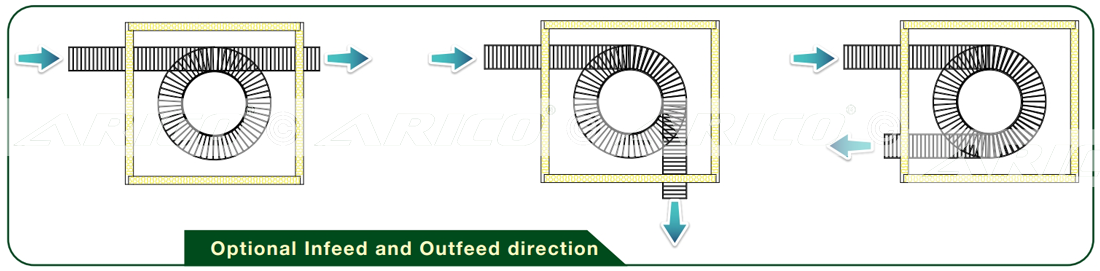

The In and Out feed position can be optimized and tailor made base on customer’s need.

Complex cascade Spiral System can be designed and built for particular purpose.

There are three driven types can be applied:

Advanced Freezing Technology:

We first successfully manufactured Spiral IQF in 2000, started with Single Tower and Drum Driven System. After years of continuous researching, developing and innovation, now we can provide a wide range of and complex Spiral System from Double Tower to Double Belt system, from Drum Driven System to Self-Stacking / Self-Supporting or Stage to Stage System.

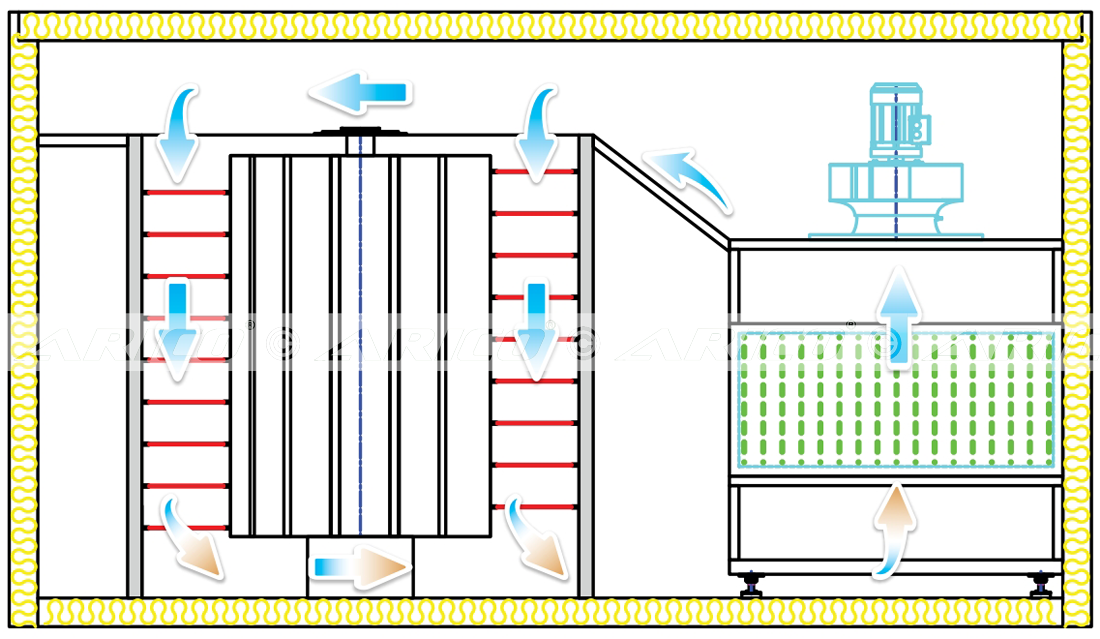

With our experiences and knowledge, we proudly to announce that we can completely control the internal air flow technology in each solution.

Spiral System will be the best solution for food process that requires long to very long processing time (normally around 10 minutes to 2 hours)

Efficiency and High productiveness:

Arico Spiral System is designed for continuous high production with 1 or 2 towers and downward or upward In/Out Feed which are synchronously or independently belt speed controlled.

As the food demand is going up day by day, the Food processors always require a high productive equipment that is not only able to considerably increase their productiveness, but also remarkably reduce the CPU (Cost Per Unit) and OMC (Operation and Maintenance Cost). Arico Spiral Systems are not standing out of this trend, with designed capacity up to 4000 Kg/Hr (in case Spiral IQF with standard product is PTO 16/20) and AAD system (Automatic Air Defrost) along with CIP (Clean in Place), it provides more than 24 hours non-stop operating and reduces the defrosting and cleaning time a half compares to conventional Spiral System.

Quality and Hygiene Design:

Spiral System is designed with fully stainless steel and food grade materials enclosure; full-welded floor and sturdy structure. Not only that, but also, the “Access everywhere” and “Easy to Clean” design criteria are immersed into Arico Spiral System, thus ensure our Quality and Hygiene Policy.

It allows easy and effective cleaning even after years running with CIP System, satisfying the highest food safety requirements, especially in Ready to Eat Food Industry.

Low Energy Consumption Innovation:

Nowadays, Go Green is our motto that leads us to be more responsible to the world we live. With the help from powerful computers, we calculate and optimize the air flow; design the sturdy structure that reduces the pressure drop, eliminates the vortex, and decrease the air loss; improve the refrigerant distribution in the evaporator; then resulting a Unique Spiral System with less power required for fans and less refrigeration capacity requirement from the system.

Short Delivery and Capacity Expandability:

Technically, Arico Spiral System is design in standard model that help shortening designing and manufacturing steps. The assembling and dry testing process are also effortless and takes less time than ever before.

The Quality Control Process also benefit from this design style when it allows our QC easily checking and detecting non-conformity points before shipping as everything is standardized from the designing step.

Furthermore, the modular design make Capacity Expandability become possible by assembling additional modules (tower) to Arico Spiral System (only available with Upward Out Feed model, please contact us if you have particular requirements

Tailor-made Solution and Customization:

As a Design and Build Contractor, our designs are flexible to every customer’s need. Out of standard modular design, we also offer a customized The Spiral System that meets your requirement and condition. If you have any problem, please leave it to us.